material science and engineering pdf

Material Science and Engineering explores the relationship between material structures and properties, driving innovation in engineering applications across various industries, from aerospace to healthcare.

1.1 Overview of Material Science and Engineering

Material Science and Engineering (MSE) is an interdisciplinary field studying the structure, properties, and applications of materials. It bridges physics, chemistry, and engineering to design and develop materials like metals, polymers, ceramics, and composites. MSE focuses on understanding how material structures at atomic and macroscopic levels influence their mechanical, thermal, and electrical properties. This knowledge enables the creation of materials tailored for specific applications, from biomedical devices to aerospace components. By integrating fundamental principles with practical engineering, MSE drives innovation in technology and industry, addressing challenges in performance, sustainability, and cost-effectiveness.

1.2 Importance of Materials in Engineering Applications

Materials are fundamental to engineering, as their properties determine the safety, durability, and efficiency of structures and devices. Advances in materials science enable innovations in industries like automotive, aerospace, and healthcare. The right material selection ensures optimal performance, cost-effectiveness, and environmental sustainability. For instance, high-strength alloys reduce weight in airplanes, while biocompatible polymers enhance medical implants. Understanding material behavior under stress, temperature, and corrosion is critical for designing reliable systems. Thus, materials science and engineering play a pivotal role in addressing global challenges and driving technological progress across all engineering disciplines.

Fundamental Principles of Material Science

Material science focuses on the structure-property relationship, emphasizing atomic structure, crystallinity, and phase diagrams. These principles guide understanding material behavior and engineering applications.

2.1 Structure-Property Relationships in Materials

Material properties are directly influenced by their internal structure, including atomic arrangements, crystallography, and phase compositions. Understanding these relationships is crucial for engineering applications, as it allows for tailored material design. Atomic structure determines properties like strength, ductility, and thermal conductivity. Crystallinity affects mechanical and optical behaviors, while phase diagrams reveal how materials transform under varying conditions. This foundational knowledge enables engineers to predict and optimize material performance for specific uses, ensuring reliability and efficiency in diverse industries, from aerospace to electronics.

2.2 Key Concepts: Atomic Structure, Crystallinity, and Phase Diagrams

Atomic structure determines how atoms are arranged within materials, influencing their properties. Crystallinity refers to the ordered arrangement of atoms, affecting strength, conductivity, and optical properties. Phase diagrams illustrate material states under varying conditions, such as temperature and pressure, guiding processing and design. Understanding these concepts is fundamental for predicting material behavior, enabling engineers to optimize properties for specific applications. These principles form the basis of material science, linking microstructure to macroscopic performance across metals, ceramics, polymers, and composites.

Types of Engineering Materials

Engineering materials include metals, polymers, ceramics, and composites, each with unique properties like strength, ductility, and thermal conductivity, tailored for specific applications and environments.

3.1 Metallic Materials: Properties and Applications

Metallic materials, such as steel, aluminum, and titanium, are widely used in engineering due to their high strength, ductility, and thermal conductivity. Metals are versatile, offering excellent mechanical properties for structural applications. Their ability to withstand stress and deform without breaking makes them ideal for construction, transportation, and machinery. Additionally, metals like copper and silver are valued for their electrical conductivity, enabling their use in electronics and wiring. The alloying of metals further enhances their properties, tailoring them for specific industries, from aerospace to consumer goods, ensuring reliability and performance in diverse environments.

3.2 Polymeric, Ceramic, and Composite Materials: Characteristics and Uses

Polymeric materials, such as plastics and elastomers, offer flexibility, lightweight, and resistance to corrosion, making them ideal for applications like packaging, medical devices, and adhesives. Ceramic materials are known for their hardness, high-temperature resistance, and brittleness, commonly used in electronics, thermal insulation, and biomedical implants. Composite materials combine two or more materials, enhancing strength and stiffness while reducing weight, making them critical in aerospace, automotive, and sports equipment. Each class of materials provides unique properties tailored to specific industrial needs, driving advancements in technology and design across various sectors.

Material Properties and Behavior

Material properties, including strength, toughness, and conductivity, determine their suitability for specific applications, influencing performance under various conditions like stress, temperature, and environmental factors.

4.1 Mechanical Properties: Strength, Ductility, and Fracture Mechanics

Understanding mechanical properties is crucial for material selection and design. Strength refers to a material’s ability to withstand external forces without deformation or fracture. Ductility measures how much a material can deform plastically before breaking, while fracture mechanics examines the propagation of cracks leading to failure. These properties are essential for predicting material behavior under stress, ensuring safety and reliability in engineering applications. Advanced testing methods, such as tensile tests and fracture toughness analysis, are used to evaluate these properties, enabling the development of materials tailored for specific industries, from aerospace to construction. Accurate analysis prevents catastrophic failures and optimizes performance.

4.2 Thermal and Electrical Properties: Conductivity and Stability

Thermal and electrical properties are critical in material selection for various applications. Thermal conductivity measures how well heat is transferred within a material, while specific heat capacity indicates the amount of heat required to change its temperature. These properties are vital for applications like insulation and heat management. Electrical conductivity reflects a material’s ability to conduct electricity, essential for electronics and wiring. Dielectric strength determines insulation performance under electric fields. Thermal and electrical stability ensure materials maintain their properties under varying conditions, preventing degradation and ensuring reliable performance in diverse engineering environments, from consumer electronics to aerospace components.

Applications of Material Science and Engineering

Material Science and Engineering impacts aerospace, energy, healthcare, and electronics. It enables advanced composites, biomedical devices, and sustainable energy solutions, driving innovation across industries globally.

5.1 Structural Applications: Metals, Alloys, and Composites

Metals, alloys, and composites are fundamental in structural engineering due to their strength, durability, and adaptability. Steel alloys are widely used in construction for buildings and bridges, offering high strength and resistance to environmental factors. Aluminum alloys are favored in aerospace applications for their lightweight properties and corrosion resistance. Composites, such as carbon fiber reinforced polymers, provide exceptional strength-to-weight ratios, making them ideal for advanced aerospace and automotive structures. These materials are essential in designing safe, efficient, and long-lasting infrastructure, highlighting the critical role of material selection in modern engineering.

5.2 Electronic and Functional Applications: Semiconductors and Smart Materials

Semiconductors are pivotal in electronic devices, enabling advancements in computing, communication, and energy systems. Silicon, a key semiconductor, drives the microelectronics industry, while emerging materials like graphene and carbon nanotubes offer enhanced electrical and thermal properties. Smart materials, such as piezoelectrics and shape-memory alloys, adapt to environmental changes, enabling applications in sensors, actuators, and medical devices. These materials integrate functionality and intelligence, revolutionizing industries from healthcare to aerospace. Their unique properties optimize performance, efficiency, and adaptability, making them indispensable in modern technology and innovation.

Recent Advancements in Material Science

Recent advancements include AI-driven material discovery, nanotechnology innovations, and sustainable material development, revolutionizing industries through enhanced performance and eco-friendly solutions.

6.1 Biomaterials and Nanomaterials: Emerging Trends

Biomaterials and nanomaterials are revolutionizing medicine and technology, offering biocompatible solutions for tissue engineering and drug delivery. Nanomaterials, with their unique size-dependent properties, enhance thermal and electrical conductivity. Researchers are developing self-healing materials and nanostructured surfaces for medical implants, reducing infection risks. Sustainable nanomaterials, like graphene and carbon nanotubes, are being integrated into energy storage and electronics. Advances in bio-inspired materials mimic natural structures, such as lotus leaves for self-cleaning surfaces. These innovations address global challenges, including healthcare and environmental sustainability, driving future technological advancements.

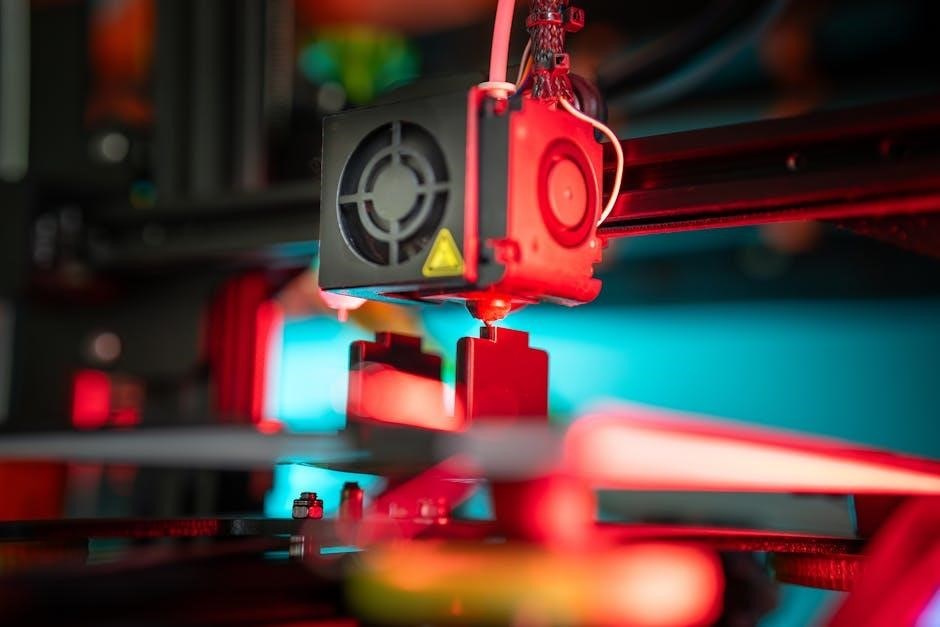

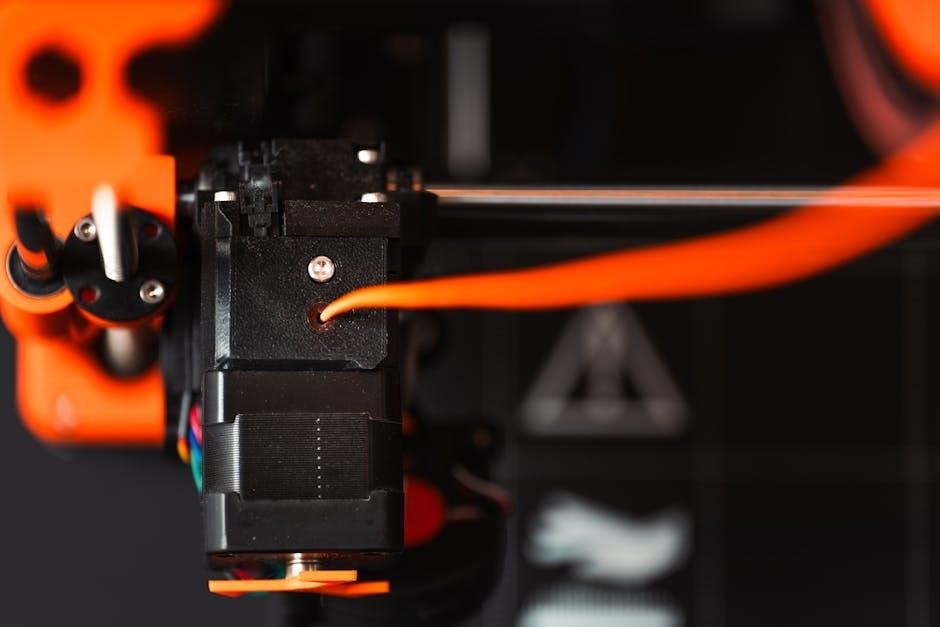

6.2 Sustainable and Advanced Manufacturing Techniques

Sustainable and advanced manufacturing techniques are transforming material production, prioritizing eco-friendly processes and resource efficiency. Additive manufacturing, such as 3D printing, enables complex geometries with minimal material waste. Green manufacturing focuses on reducing environmental impact by using recycled materials and renewable energy. Advanced techniques like laser processing and precision casting improve material performance while lowering energy consumption. Integration of AI and machine learning optimizes production workflows, enhancing quality and sustainability. These innovations are critical for meeting global demand for high-performance materials while addressing environmental and economic challenges, driving the future of manufacturing in industries from aerospace to healthcare.

Education and Curriculum Development

Material science and engineering education is evolving, with curricula integrating new materials, sustainable practices, and advanced technologies to prepare students for modern industrial challenges and innovations.

7.1 Teaching Approaches in Material Science and Engineering

Modern teaching approaches in material science and engineering integrate interactive tools, such as computer simulations and virtual labs, to enhance student engagement. These methods allow learners to explore material behavior and properties dynamically. Project-based learning is emphasized, enabling students to apply theoretical concepts to real-world challenges. Collaborative efforts between academia and industry ensure practical relevance, preparing graduates for emerging trends in materials innovation. Hands-on experiments and case studies further bridge the gap between theory and application, fostering a deeper understanding of material science principles.

7.2 Role of Laboratories and Practical Training in MSE Education

Laboratories and practical training are cornerstone components of material science and engineering education, providing students with hands-on experience to apply theoretical concepts. State-of-the-art facilities enable experimentation with advanced materials, allowing students to analyze properties, observe behaviors, and understand processing techniques. Practical training fosters problem-solving skills, equipping students to address real-world engineering challenges. By engaging in mechanical testing, microstructural analysis, and materials synthesis, students gain a deeper understanding of structure-property relationships, preparing them to innovate and design materials for diverse applications.

Future Trends in Material Science and Engineering

Future trends include integrating sustainable practices, advanced nanomaterials, and AI-driven material design, focusing on eco-friendly solutions, smart materials, and innovative manufacturing techniques to meet global challenges.

8.1 Impact of AI and Computational Modeling on Material Design

AI and computational modeling are revolutionizing material design by accelerating the discovery of new materials. Machine learning algorithms analyze vast datasets to predict material properties, reducing experimental costs and time. Computational simulations enable precise modeling of material behavior under various conditions, optimizing performance and reliability. These tools also facilitate reverse engineering and the development of tailored materials for specific applications, enhancing sustainability and innovation. By streamlining the design process, AI and computational techniques are driving advancements in fields like energy storage, aerospace, and electronics, ensuring faster and more efficient material development cycles.

8.2 Challenges and Opportunities in the Field of MSE

The field of Material Science and Engineering faces challenges such as developing sustainable materials, reducing environmental impact, and addressing global resource limitations. Opportunities arise from advancements in nanotechnology, biomaterials, and smart materials, which enable innovative applications in healthcare, energy, and electronics. Collaborative research and interdisciplinary approaches are essential to overcome these challenges. Additionally, the integration of AI and computational tools offers transformative potential for material discovery and optimization. Educating the next generation of engineers and fostering global collaboration will further accelerate progress, ensuring MSE continues to drive technological and societal advancements.