concrete reinforcing steel institute manual of standard practice pdf

The Concrete Reinforcing Steel Institute Manual of Standard Practice provides comprehensive guidelines for reinforced concrete construction, detailing best practices, design standards, and fabrication techniques for professionals.

1.1 Purpose and Scope of the Manual

The Concrete Reinforcing Steel Institute Manual of Standard Practice serves as a definitive guide for professionals involved in reinforced concrete construction. Its primary purpose is to establish standardized practices, ensuring consistency and quality in design, fabrication, and placement of reinforcing steel. The manual covers essential aspects such as load calculations, material specifications, and construction techniques, providing a comprehensive reference for engineers, contractors, and fabricators. It reflects current industry codes and standards, addressing key areas like reinforcement detailing, tolerances, and quality control. By adhering to this manual, practitioners can ensure compliance with best practices, enhancing the safety and durability of reinforced concrete structures.

1.2 Key Features of the 27th Edition

The 27th Edition of the Concrete Reinforcing Steel Institute Manual of Standard Practice introduces updated guidelines aligned with modern construction standards. It includes revised sections on reinforcing bar detailing, fabrication tolerances, and placement requirements. Enhanced content on material specifications ensures compliance with current codes, while new sections address advancements in concrete technology. The edition also incorporates corrections and clarifications from previous versions, improving accuracy and usability. Additionally, it provides updated tables and references, serving as an invaluable resource for professionals seeking to implement best practices in reinforced concrete design and construction. These features ensure the manual remains a trusted reference for the industry.

Design Considerations

Design considerations focus on ensuring structural integrity, durability, and compliance with codes. Proper detailing and material selection are critical to achieve optimal performance in reinforced concrete structures.

2.1 Load Calculations and Reinforcement Requirements

Load calculations are essential to determine the structural demands on reinforced concrete members. The CRSI Manual provides detailed guidelines for calculating dead, live, and environmental loads. Proper reinforcement requirements ensure that steel quantities and placements meet design specifications, preventing structural failure. Tables and charts within the manual assist engineers in selecting appropriate bar sizes and spacing to resist tensile and compressive forces. Compliance with building codes and material standards is emphasized to ensure safety and durability. Accurate calculations and adherence to these requirements are critical for achieving optimal structural performance in reinforced concrete construction projects.

2.2 Design of Reinforced Concrete Members

The manual offers detailed guidance on designing reinforced concrete members, including beams, columns, slabs, and foundations. It outlines principles for ensuring strength, durability, and serviceability. Engineers can find procedures for calculating section dimensions, reinforcement ratios, and spacing to meet structural demands. The manual also provides recommendations for detailing reinforcement to resist shear, flexure, and axial forces. Compliance with current codes and standards is highlighted to ensure design safety and efficiency. Practical examples and case studies illustrate how to apply these principles effectively, making the manual an indispensable resource for engineers involved in reinforced concrete design and construction.

Materials and Specifications

This section details types of reinforcing steel, including ASTM standards for billet-steel bars, rail, and axle steel. It specifies material tolerances, chemical requirements, and physical properties.

3.1 Types of Reinforcing Steel

The manual categorizes reinforcing steel into several types, including billet-steel bars, rail steel, and axle steel, each with specific ASTM standards. Grade 40, 50, and 60 steels are commonly specified, differing in yield strength and applications. Weldable steels, such as ASTM A615 and A706, are highlighted for their suitability in welded construction. The document also covers epoxy-coated and galvanized reinforcements for corrosion resistance. These specifications ensure compatibility with various concrete designs and environmental conditions, providing engineers with a robust framework for material selection and compliance with industry standards. This section is vital for understanding the mechanical and physical properties of reinforcing steel.

3.2 Material Tolerances and Standards

The manual outlines rigorous material tolerances to ensure compliance with industry standards, including ASTM specifications for steel reinforcement. Tolerances for bar dimensions, such as diameter and length, are specified to maintain consistency. Standards for surface conditions, including the absence of deleterious substances, are emphasized to prevent defects. Additionally, requirements for epoxy coatings and galvanized finishes are detailed, ensuring durability and corrosion resistance. These guidelines align with ACI and CRSI recommendations, providing a unified approach to material quality control. Adherence to these standards is crucial for achieving structural integrity and long-term performance in reinforced concrete construction, making this section indispensable for fabricators and inspectors.

Fabrication and Detailing

This section covers fabrication processes, detailing requirements, and quality control measures for reinforcing steel, ensuring precise bar placement and compliance with design specifications and standards.

4.1 Reinforcing Bar Detailing Requirements

The CRSI Manual of Standard Practice outlines specific detailing requirements for reinforcing bars, ensuring compliance with ACI standards and project specifications. Proper placement, spacing, and orientation of bars are emphasized to maintain structural integrity. Details include bend diameters, hook lengths, and stirrup/tie configurations, with particular attention to beams, girders, and other structural members. The manual also addresses bar lengths, cutoffs, and lap splices, providing clear guidelines to avoid construction errors. Adherence to these requirements ensures that reinforcing steel is fabricated and detailed accurately, meeting both design and safety standards effectively. Compliance with these specifications is crucial for achieving durable and high-performance reinforced concrete structures.

4.2 Fabrication Tolerances and Quality Control

The CRSI Manual of Standard Practice establishes fabrication tolerances and quality control measures to ensure precision in reinforcing steel production. It specifies allowable deviations in bar lengths, bends, and placement to maintain structural integrity. Quality control processes include inspections of materials, welding, and surface conditions to prevent defects. The manual emphasizes documentation and corrective actions for non-conforming items, ensuring compliance with industry standards. These guidelines help fabricators maintain consistency and reliability, ultimately contributing to the safety and performance of reinforced concrete structures. Adherence to these standards is essential for meeting project specifications and achieving long-term durability in construction projects.

Placement and Construction

This section outlines guidelines for placing reinforcing bars, ensuring proper spacing, alignment, and field inspection to maintain structural integrity and compliance with quality standards.

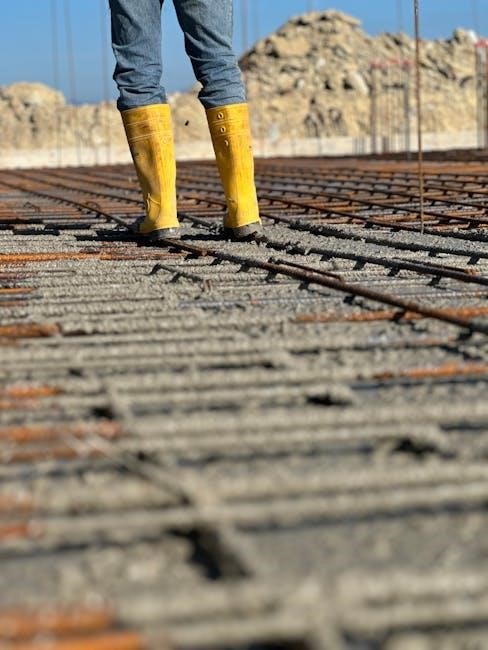

5.1 Placement of Reinforcing Bars

The proper placement of reinforcing bars is critical to ensure structural integrity. Bars must be free of mud, oil, or deleterious substances before placement. They should be accurately positioned to maintain correct spacing and alignment, with supports and chairs used to hold them in place. Field inspections are essential to verify compliance with design specifications and standards. The manual emphasizes maintaining cleanliness and avoiding damage during placement. Specific requirements for lap splicing, tie hooks, and beam placements are detailed to ensure durability and safety. Adherence to these guidelines ensures high-quality construction and compliance with industry standards for reinforced concrete structures.

5.2 Field Inspection and Quality Assurance

Field inspection and quality assurance are vital to ensuring compliance with design and construction standards. Inspectors must verify the placement, spacing, and cleanliness of reinforcing bars before concrete placement. The manual outlines specific checks for lap splices, hooks, and supports. Documentation of inspections is required to maintain accountability and ensure all elements meet specified requirements. Quality assurance processes involve regular monitoring of materials and workmanship, with corrective actions taken promptly for any deficiencies. This systematic approach ensures the final structure meets safety, durability, and performance expectations, aligning with industry codes and best practices for reinforced concrete construction. Proper field oversight is essential for achieving long-term structural integrity.

References and Further Reading

For detailed guidance, refer to ACI 318 Building Code Requirements for Reinforced Concrete and the Concrete Reinforcing Steel Institute Manual of Standard Practice. Additional resources are available at CRSI.

6.1 List of Referenced Standards and Codes

The manual references several key standards and codes, including ACI 318 Building Code Requirements for Reinforced Concrete and the Concrete Reinforcing Steel Institute Manual of Standard Practice. Additional standards such as ASTM A615 for reinforcing bars, ASTM A706 for low-alloy steel, and ACI 350.5 for post-tensioning are also cited. These documents provide foundational guidelines for design, materials, and construction practices in reinforced concrete. Compliance with these standards ensures structural integrity and adherence to industry best practices. Referencing these codes is essential for engineers, contractors, and fabricators involved in reinforced concrete projects.

6.2 Additional Resources for Reinforced Concrete Design

Beyond the manual, additional resources include the Concrete Reinforcing Steel Institute (CRSI) website, offering technical notes, design guides, and webinars. The Canadian edition of the manual provides region-specific practices. ACI 318 Building Code Requirements and ASTM standards are essential for detailed design. For post-tensioning, ACI 350.5 is a key reference. Online courses and industry publications further enhance knowledge. These resources support engineers, contractors, and fabricators in staying updated on best practices and code compliance, ensuring reinforced concrete structures are safe, durable, and meet modern engineering standards. They complement the manual, offering in-depth insights for complex designs and construction challenges.